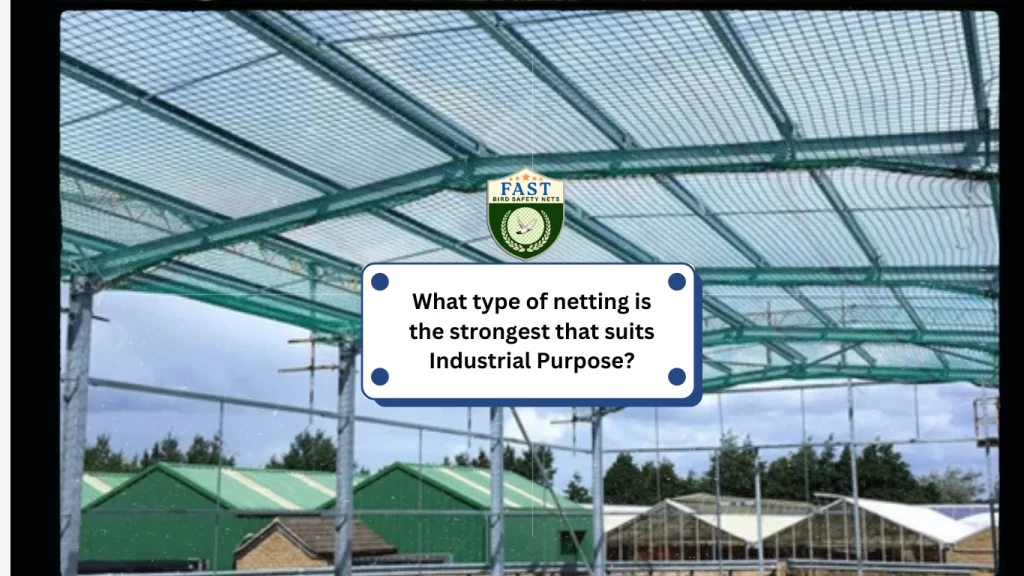

Industrial operations often face challenges posed by birds, ranging from potential damage to equipment, contamination of products, to safety hazards. To mitigate these risks, industrial bird netting has emerged as a crucial solution. Among various materials available, HDPE (High-Density Polyethylene) and Nylon nets stand out for their exceptional strength and durability, making them ideal choices for industrial bird netting applications. This article delves into the characteristics, advantages, and applications of HDPE/Nylon nets, highlighting why they are the top choice for industrial purposes.

Understanding Industrial Bird Netting:

Industrial bird netting serves as a protective barrier against avian intruders, preventing them from accessing sensitive areas within industrial facilities such as warehouses, factories, and processing plants. These nets are designed to withstand harsh environmental conditions, frequent use, and potential bird-related damage.

Key Features of HDPE/Nylon Nets:

HDPE and Nylon are two materials renowned for their strength, durability, and resistance to abrasion, chemicals, and UV radiation. When woven into nets, they offer several key features essential for industrial bird netting:

Strength: HDPE/Nylon nets are exceptionally strong, capable of withstanding considerable tension and impact. This strength is vital for ensuring that the net remains intact even under challenging conditions.

Durability: These nets boast impressive durability, maintaining their structural integrity over extended periods. They are resistant to tears, punctures, and degradation, providing long-term protection against bird intrusion.

UV Resistance: Industrial environments often expose nets to prolonged sunlight, which can cause deterioration over time. HDPE/Nylon nets are UV-resistant, ensuring prolonged lifespan and consistent performance even in outdoor settings.

Chemical Resistance: Industrial facilities may use various chemicals in their operations, posing a risk of corrosion or degradation to the netting material. HDPE/Nylon nets are resistant to a wide range of chemicals, ensuring reliable protection without compromising their integrity.

Advantages of HDPE/Nylon Nets for Industrial Bird Netting:

Superior Strength: HDPE/Nylon nets offer unmatched strength compared to other materials such as polyester or polypropylene. This strength is crucial for withstanding high tension and potential impacts, ensuring reliable protection against bird intrusion.

Enhanced Durability: With their exceptional durability, HDPE/Nylon nets require minimal maintenance and replacement, reducing overall operational costs for industrial facilities. They can withstand harsh environmental conditions and frequent use without compromising performance.

Customizable Options: Industrial bird netting requirements vary depending on the specific application and site characteristics. HDPE/Nylon nets are available in a range of sizes, mesh configurations, and thicknesses, allowing for customization to suit diverse industrial needs.

Versatile Applications: HDPE/Nylon nets are suitable for a wide range of industrial applications, including warehouses, food processing plants, agricultural facilities, and manufacturing sites. They provide effective protection against birds while maintaining airflow and visibility, ensuring compatibility with various operational requirements.

Regulatory Compliance: Many industries are subject to regulatory requirements regarding bird control and hygiene standards. HDPE/Nylon nets help industrial facilities comply with these regulations by providing an effective barrier against avian pests, thereby safeguarding product quality and safety.

Case Studies:

Warehouse Protection: A large distribution warehouse implemented HDPE/Nylon bird netting to protect its inventory from bird damage and contamination. The robust netting solution effectively prevented birds from roosting and nesting in the facility, ensuring a clean and sanitary environment for stored goods.

Food Processing Facility: A food processing plant installed HDPE/Nylon nets to safeguard its production area from bird intrusion. The durable netting material withstood frequent cleaning procedures and maintained its integrity, preventing birds from accessing sensitive processing areas and minimizing the risk of product contamination.

Conclusion:

Industrial bird netting plays a crucial role in protecting industrial facilities from the detrimental effects of bird intrusion. HDPE/Nylon nets, with their superior strength, durability, and resistance to environmental factors, emerge as the top choice for industrial applications. By investing in high-quality HDPE/Nylon bird netting, industrial facilities can effectively mitigate bird-related risks, ensure regulatory compliance, and maintain a safe and hygienic working environment.